Holidaypac

Holidaypac

Jan 20,2026

Jan 20,2026

"One corner collapsed after two days."

It’s the email no brand manager ever wants to open. Picture this: You’ve spent hundreds of dollars on a custom POS (Point of Sale) run. You’ve negotiated with the retailer for prime floor space. The units arrive, the merchandisers set them up, and your product looks great.

Then, 48 hours later, you get the photo. The display has buckled. Your premium olive oil or high-end cosmetics are rolling around on the dirty supermarket floor. It’s not just a mess; it’s a direct hit to your brand's reputation.

Here’s the thing: A cardboard display isn't just "paper." It is a temporary shelf that carries your revenue. If the structural integrity fails, the marketing doesn't matter.

At Holidaypac, we’ve spent over 20 years engineering displays that stay upright. Let’s look at why they fail and how we ensure they don't.

The structural failure usually starts deep inside the layers of the paper itself, often due to cost-cutting on material density.

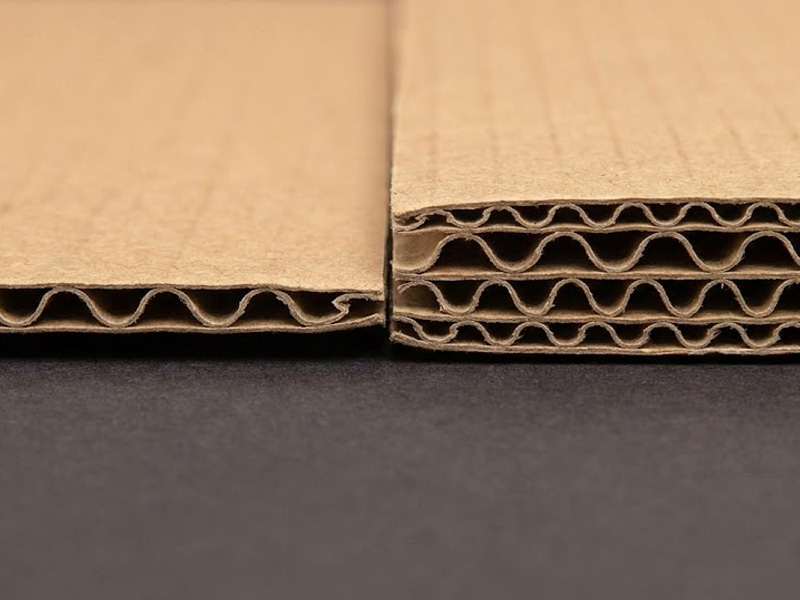

Most collapses happen because a supplier tried to save a few cents by swapping the spec. They might use a single-wall structure when the weight load clearly demanded a double-wall.

The Fix: Understanding Flutes and Layers

If you are stocking heavy items (like beverages or canned goods), standard cardboard won't cut it.

We also prioritize High-strength Corrugated Board. This isn't your standard shipping box material. It’s engineered to maintain stiffness even in high-humidity retail environments (like near grocery store fridges), where standard paper turns to mush.

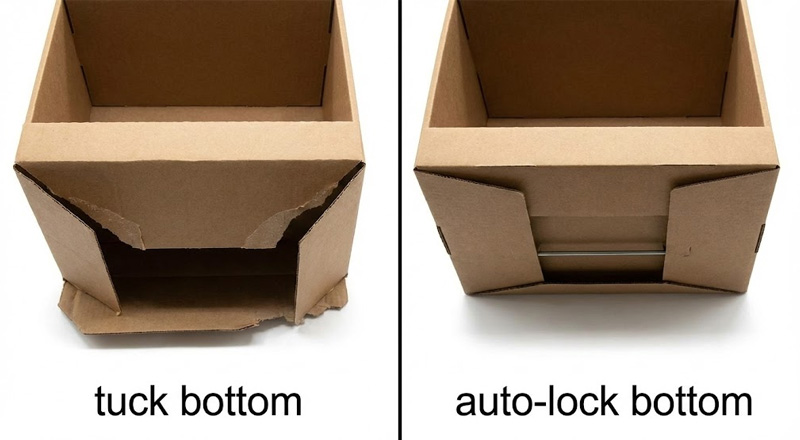

If the base isn't reinforced with locking mechanisms or additional supports, gravity will win every time.

You’ve seen this happen. A store clerk tries to shift a fully loaded display a few inches to the left, and—rip—the bottom gives out. This usually happens because the design relied on a simple "tuck bottom" (like a cereal box) for a unit holding 20kg of product.

The Fix: Metal Bars and Auto-Locks

We don't leave the foundation to chance.

Auto-lock Bottoms: For medium weights, we use a crash-lock or auto-lock bottom. When the display is popped open, the bottom flaps lock against each other, creating a floor that gets stronger the more you push down on it.

The "Heavy Metal" Approach: For heavy-duty requirements (think detergent or glass bottles exceeding 10-20kg), we integrate Metal Bars beneath the shelf or base. We also use double-layered folded cardboard supports. It’s invisible to the customer, but it makes the unit rock-solid.

Wobbly displays are usually the result of a high center of gravity and a footprint that is too narrow.

"It’s too tall and wobbly." We hear this complaint about competitors' units constantly. If a display is tall, skinny, and loaded with heavy items at the top, the physics are working against you. A shopper walking by quickly creates enough air displacement to tip a poorly balanced unit.

The Fix: Geometry and Physics

Stability isn't magic; it's engineering.

Tapered Design: We often suggest a trapezoidal shape—wide at the bottom, narrow at the top. This lowers the center of gravity and anchors the unit visually and physically.

Weighted & Waterproof Bases: Sometimes, the cardboard needs help. We can add a weighted element to the base or, better yet, a waterproof plastic tray. This protects the cardboard from mop water (a common display killer) and adds necessary ballast to the bottom.

No. Simulation is useful, but nothing beats a physical "torture test" with real products.

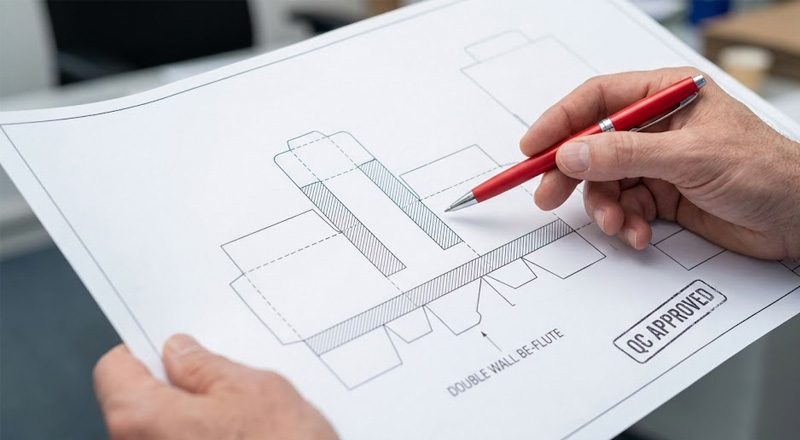

Many factories design a display, check the dimensions on a screen, and hit "print." They might assemble an empty box to check the fit, but they rarely check the endurance.

The Fix: The 72-Hour Load Test

At Holidaypac, we don't trust the software blindly. Before we launch mass production, we perform a Real World Prototype Test.

1. We build the sample.

2. We load it with the client's actual product (or water bottles equivalent to the total weight).

3. We leave it for 72 hours.

Why 72 hours? Because cardboard creates "creep." It might look fine for the first hour, but after two days of constant pressure and humidity, fibers can relax and buckle. If it’s going to fail, we want it to fail in our factory, not in your store.

If you are skimming, here is what you need to know to avoid a collapse:

Demand Double Wall: For anything heavier than chips or tissues, ask for BE-Flute (5-layer) board.

Check the Bottom: Ensure the design uses an auto-lock bottom or reinforced metal bars if the load exceeds 15kg.

Lower the Center of Gravity: Use a tapered design or a waterproof base tray to prevent tipping.

Mandatory Testing: Never approve a bulk order without seeing a photo/video of a 72-hour weight test on the prototype.

Saving a dollar on material costs feels great until you lose thousands in damaged product and retail relationships. The cost of a collapse is always higher than the cost of quality engineering.

With over two decades of experience, Holidaypac knows exactly where the stress points are. We don't just print boxes; we engineer retail solutions.

Need a second opinion on your current design?

Would you like me to review your current die-line for structural risks, or send you a video example of our 72-hour load test? Drop a comment or reach out directly.

Links