Holidaypac

Holidaypac

Jan 28,2026

Jan 28,2026

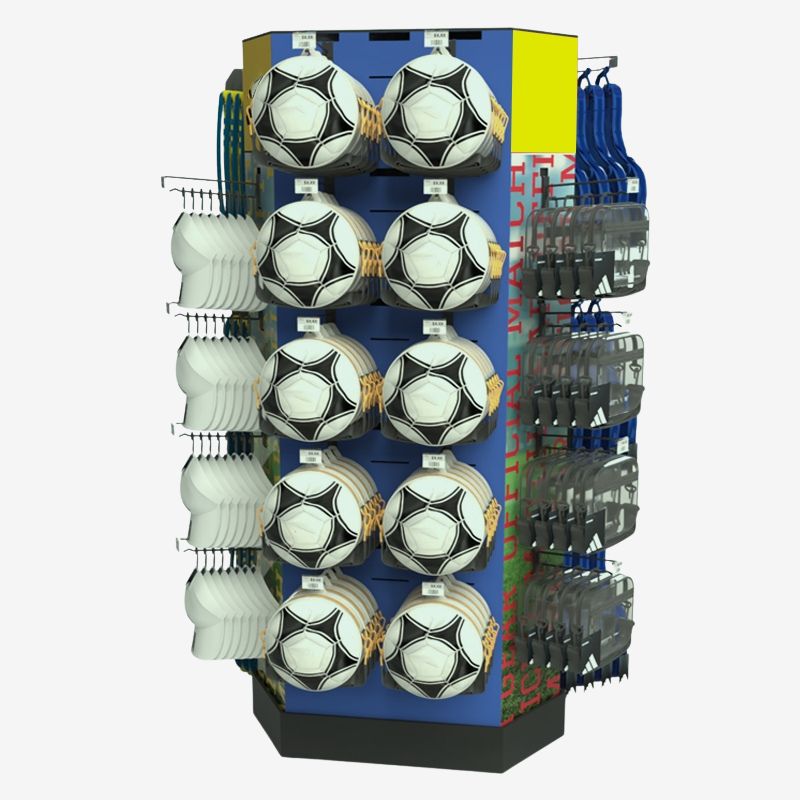

It’s tragic. You spend weeks designing the graphics, fighting over the font size, and getting the messaging just right. Then, three days after it hits the sales floor, the whole thing buckles under the weight of your own product. It’s leaning. It’s sad. And frankly, it’s making your brand look cheap.

Here’s the thing: Most people think design is about the ink. It’s not. It’s about the structural integrity of the paper beneath it.

If you want your retail presence to survive the chaos of a busy shop floor, you have to stop treating cardboard like it’s just, well, paper. Let’s talk about why your displays are failing and how to fix them without breaking the bank.

Because most brands underestimate the gravitational pull of their own inventory.

Serious talk for a second. Standard corrugated cardboard—the stuff your Amazon packages come in—is great for shipping, but it’s terrible for standing still while holding twenty pounds of shampoo bottles.

When you use single-wall, low-grade board, you are asking for the "sag." This happens when moisture in the air (or from the floor) softens the fibers, and the weight of your product crushes the flutes (the wavy middle part).

The Solution? Muscle.

You need high-strength corrugated paper. We aren't talking about standard cardboard here. You want to ask your manufacturer for double wall structures. Specifically, look for B+E pit configurations.

Why B+E? It’s a hybrid.

When you sandwich these together (double wall), you get a display that’s surprisingly rigid. It doesn't just hold your product; it fights back against gravity. It feels solid to the touch, which subconsciously tells your customer, "Hey, this product is high quality."

It’s armor first, decoration second.

Let’s be honest. Retail floors are gross. They get mopped with wet industrial cleaners, people spill coffee, and sometimes it’s just humid. Raw cardboard acts like a sponge. Once water gets into the bottom of your display, wicking action pulls it up, and suddenly your stand is collapsing like a bad soufflé.

This is where surface coating saves your bacon. You have two main heavy hitters here:

You know this look. It’s shiny, it pops, and it screams "look at me." But structurally? It’s a plastic shield. Glossy film seals the paper fibers. If a janitor mops a little too aggressively near your display, a film laminate prevents that water from soaking in immediately. It’s durable and resists scuffs from shopping carts.

If you want a more premium, understated vibe, you go matte. It feels softer and looks sophisticated under harsh fluorescent store lights because it doesn't glare. Like the glossy version, matte film provides a critical moisture barrier.

Pro tip: Don't just varnish it. Varnish is a liquid coating that dries; it’s okay, but it can crack. Film lamination is a physical sheet of plastic adhered to the board. It’s vastly superior for structural longevity.

Calculate the total load and then add a 20% safety margin.

If you are selling potato chips, standard cardboard might work. If you are selling wine bottles, motor oil, or heavy electronics, standard board is a death sentence for your display.

Think of it like building a house. You wouldn't put a slate roof on a straw hut.

Also, consider the lifespan. Is this a "flash sale" display for one weekend? Or does it need to live in a Walmart aisle for three months? The longer it stays, the stronger the material needs to be. Time degrades paper. High-strength double wall board buys you time.

So, next time you’re approving a proof for a Point of Sale (POS) display, don't just look at the colors. Ask the boring questions. Ask about the flutes. Ask about the lamination.

Because the most beautiful display in the world is worthless if it’s face-down on the floor.

Links