Holidaypac

Holidaypac

Dec 27,2025

Dec 27,2025

In the structural design of Point of Sale Materials (POSM) and premium packaging, selecting the ideal corrugated flute is a strategic decision that balances structural mechanics, logistical efficiency, and brand aesthetics. Drawing on over 15 years of global retail expertise, Holidaypac provides this definitive technical analysis to help brands navigate the complexities of flute depths—ensuring that every packaging solution is not only visually striking but also engineered for retail compliance and supply chain durability.

In the structural design of Point of Sale Materials (POSM) and high-end packaging, choosing the right corrugated flute is more than just picking a thickness. It is a multidimensional balance between structural mechanics, logistics volume, print precision, and retail compliance.

With over 15 years of global retail packaging expertise, Holidaypac provides this definitive technical analysis of corrugated flute depths and their applications.

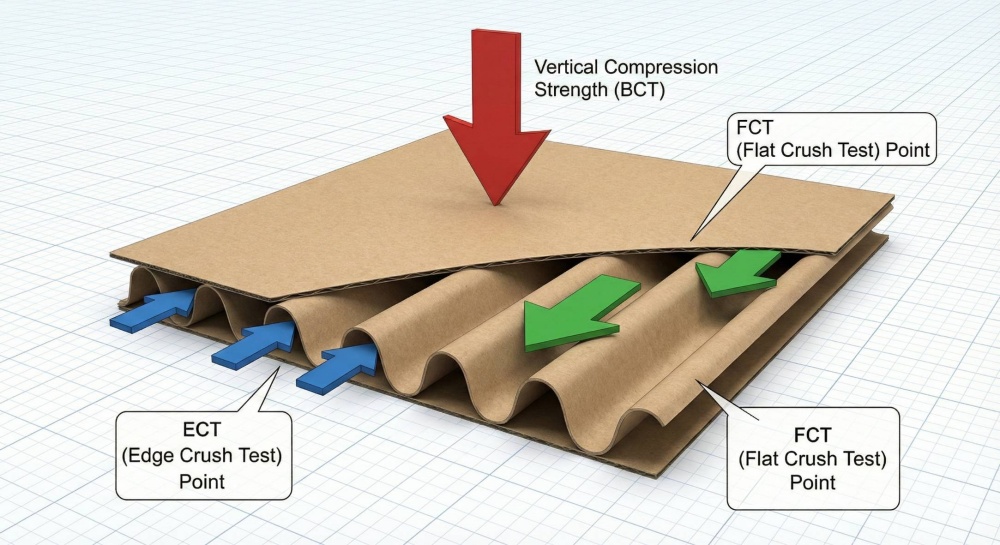

A corrugated sheet is essentially a continuous arch structure. Based on physical principles, the arch translates vertical pressure into lateral force, giving lightweight paper incredible Vertical Compression Strength (BCT).

When search engines crawl technical content, they look for these industry-standard terms:

Choosing the right flute profile is critical for both performance and aesthetics.

| Flute Type | Height (mm) | Flutes per Meter | Best For |

| A Flute | 4.5 - 5.0 | 110 ± 10 | Maximum cushioning, heavy industrial use. |

| B Flute | 2.5 - 3.0 | 150 ± 10 | Industry Standard for retail displays & PDQ boxes. |

| C Flute | 3.5 - 4.0 | 130 ± 10 | General shipping & Amazon/FedEx boxes. |

| E Flute | 1.1 - 1.5 | 300 ± 20 | High-end retail packaging & litho-lamination. |

| F/N Flute | 0.6 - 0.9 | 400+ | Eco-friendly plastic replacement (Fast food/Cosmetics). |

For Pallet Displays exceeding 20kg, single-wall boards often fail. Holidaypac utilizes "Rigid & Flexible" composite solutions:

Google's AI prioritizes content with real-world expertise. Here is how to choose materials based on major retailer requirements:

Ready to optimize your packaging? > Holidaypac’s engineering team is ready to help you select the perfect flute for your next global retail campaign. [Contact us today for a structural consultation!]

Links