Holidaypac

Holidaypac

Sep 25,2025

Sep 25,2025

When it comes to supplying one of the largest retailers in the world, compliance is not optional—it’s the rule. Walmart’s packaging guidelines are known for their precision, and for 2025, the D3 Category Box Standards set a new benchmark for how vendors in the stationery and back-to-school (BTS) category must prepare, mark, and ship their products.

Whether you are a seasoned Walmart supplier or a new manufacturer looking to get your product on their shelves, understanding and implementing these standards is essential. In this guide, we’ll break down everything you need to know—straight from the updated D3 requirements—so you can stay compliant, avoid costly chargebacks, and ensure smooth operations.

Walmart handles millions of shipments annually. Clear, standardized packaging ensures that:

The D3 Category is Walmart’s stationery and back-to-school (BTS) product group, covering everything from pencils to binders. Because of the volume and seasonality of this category, Walmart enforces stricter visibility and organization rules.

The D3 box standards cover markings, fonts, colors, labeling, and case structure. Let’s unpack each requirement.

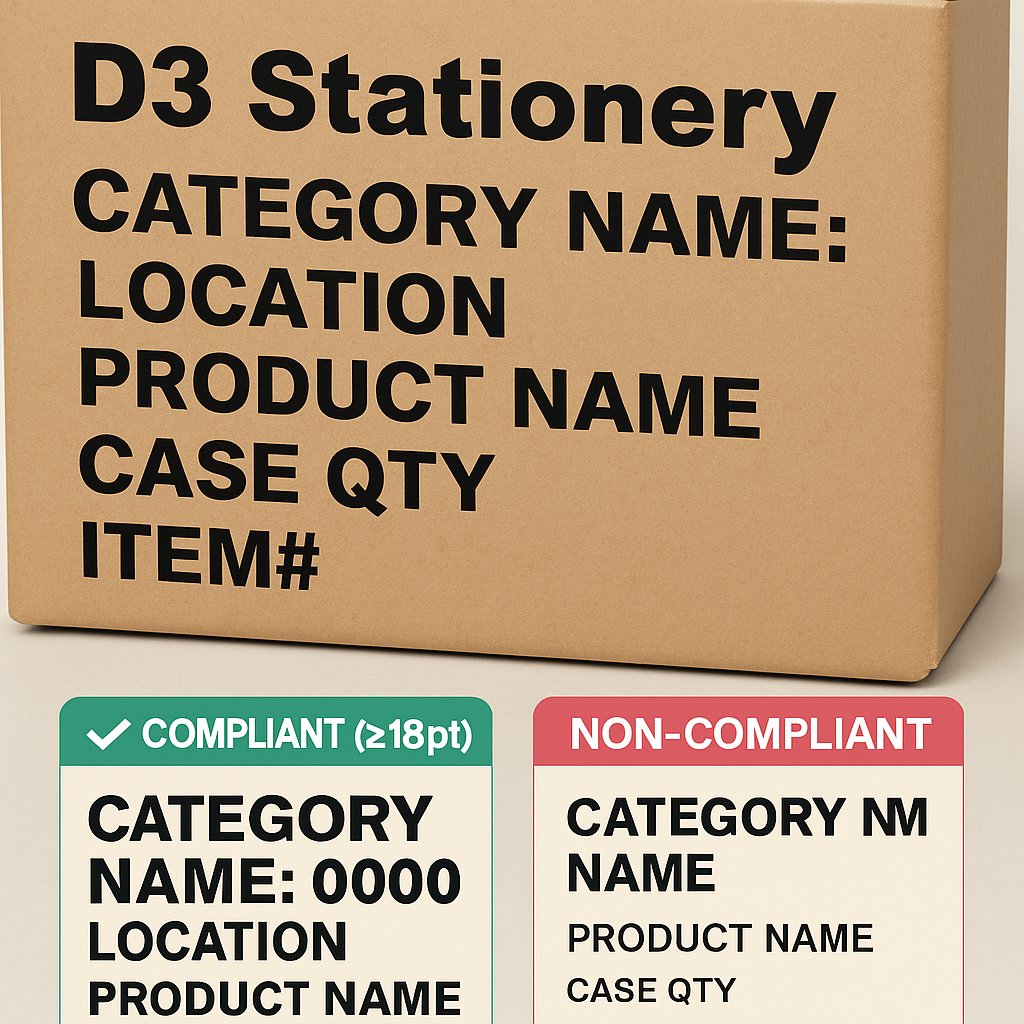

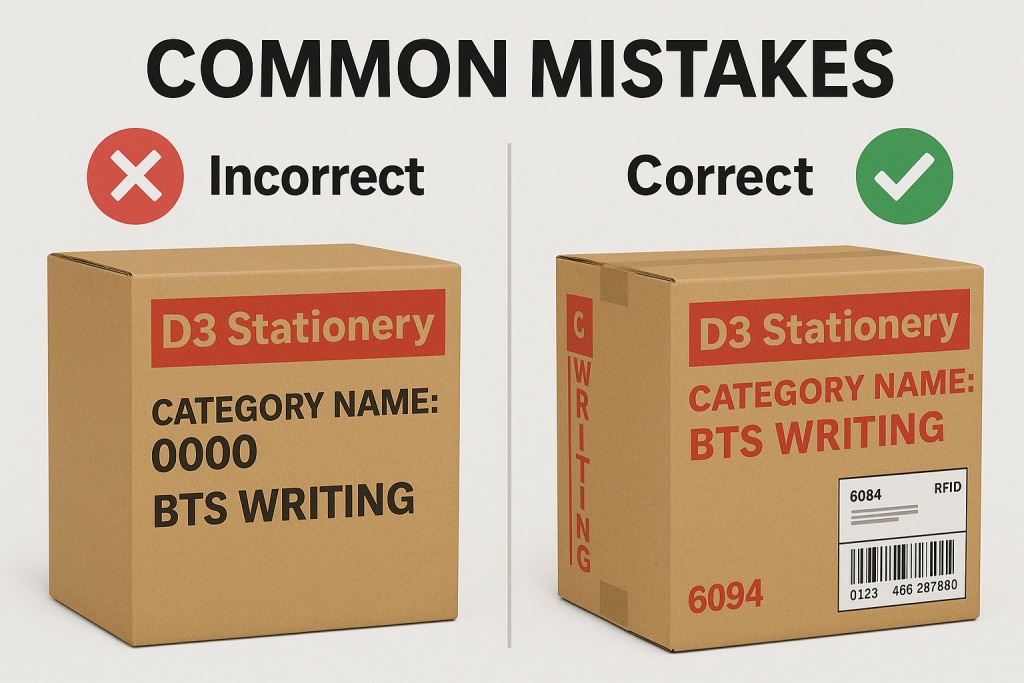

Every shipper carton must display direct print markings on all sides. This ensures visibility regardless of how the case is stacked or stored.

1.Shippers less than 7 inches tall → Print should cover ½ of the vertical space.

2.Shippers greater than 7 inches tall → Print should cover ⅔ of the vertical space.

Why this matters: Large, bold text minimizes errors in fast-moving warehouses. Associates can quickly identify contents without extra handling.

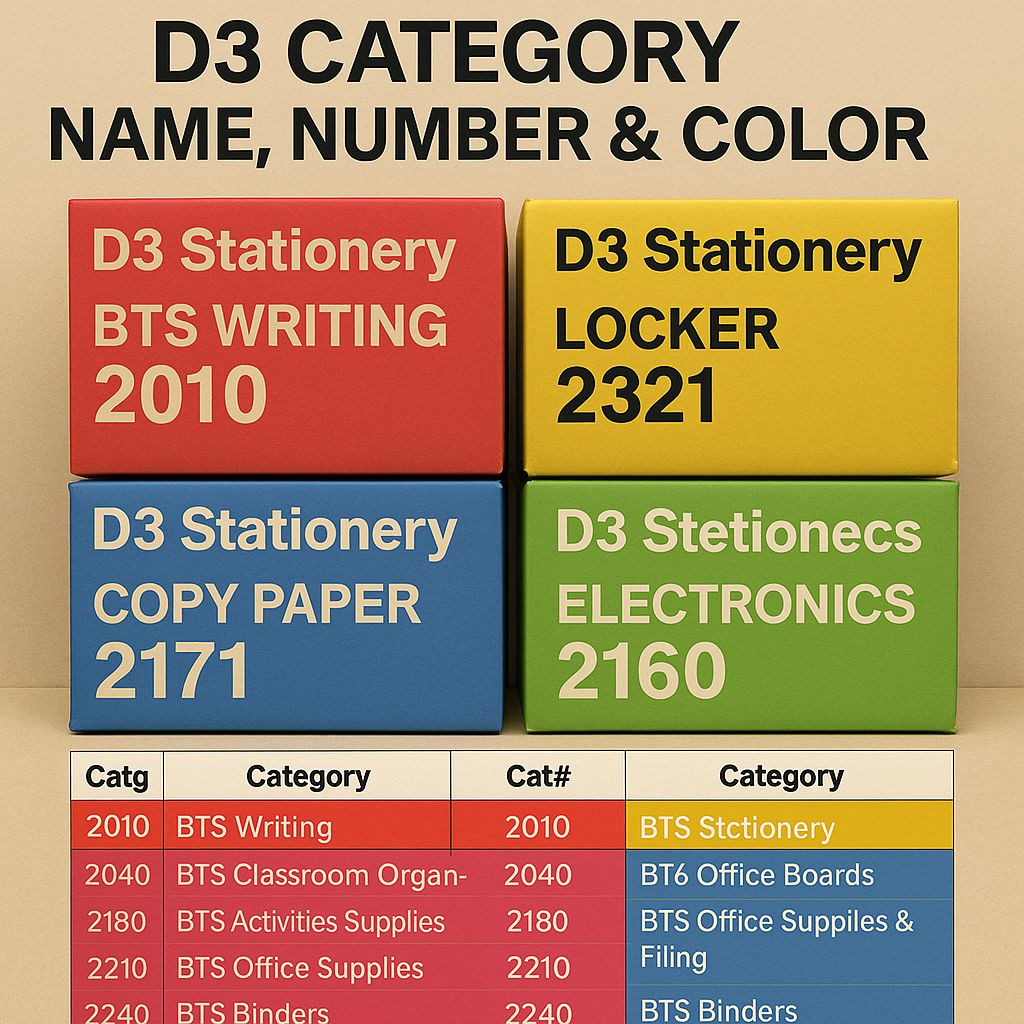

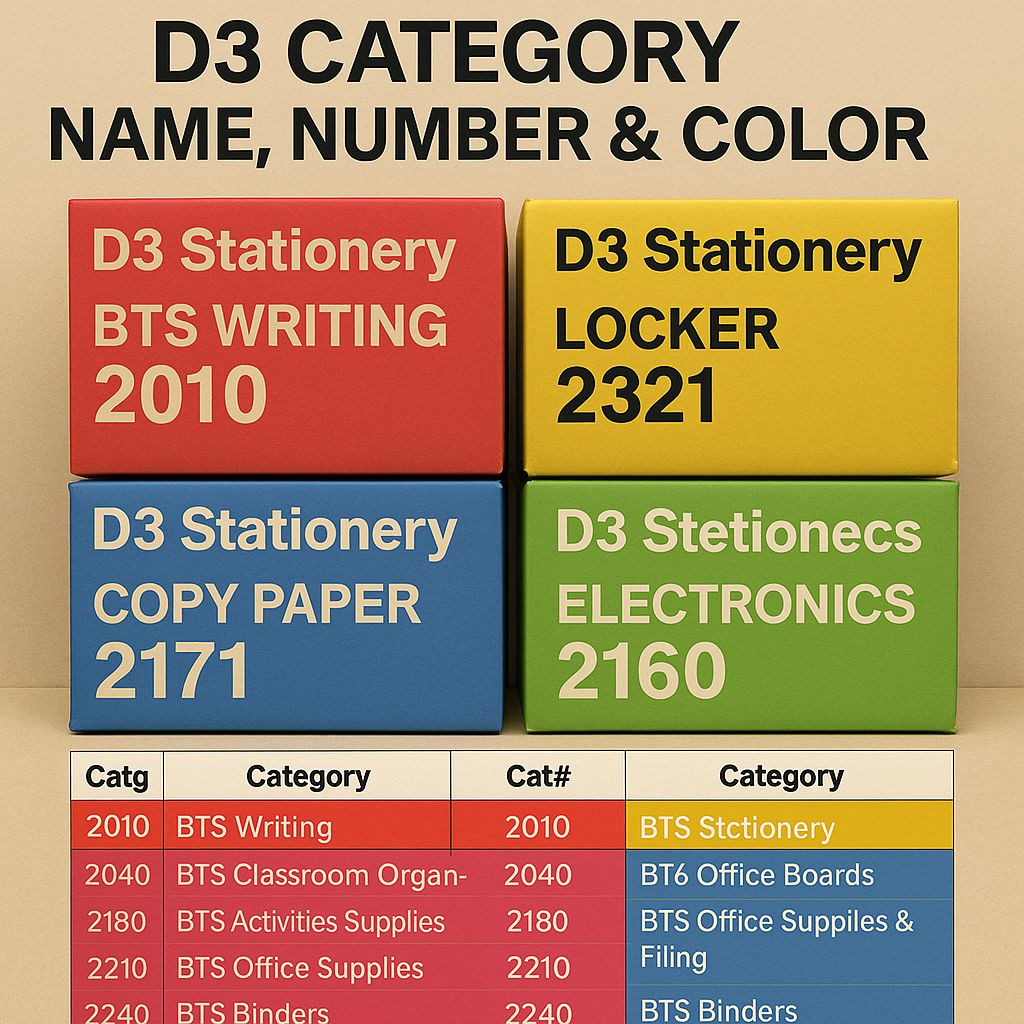

Each box must carry a category designation with category name, category number, and assigned color code.

For example:

These codes correspond to Walmart’s internal category management system.

Colors: Each subcategory has a Pantone color assigned for visual identification. Examples include:

Why this matters: Visual color coding accelerates stock sorting. Imagine a back-to-school truck arriving with hundreds of cartons—clear category color signals make staging and unpacking seamless.

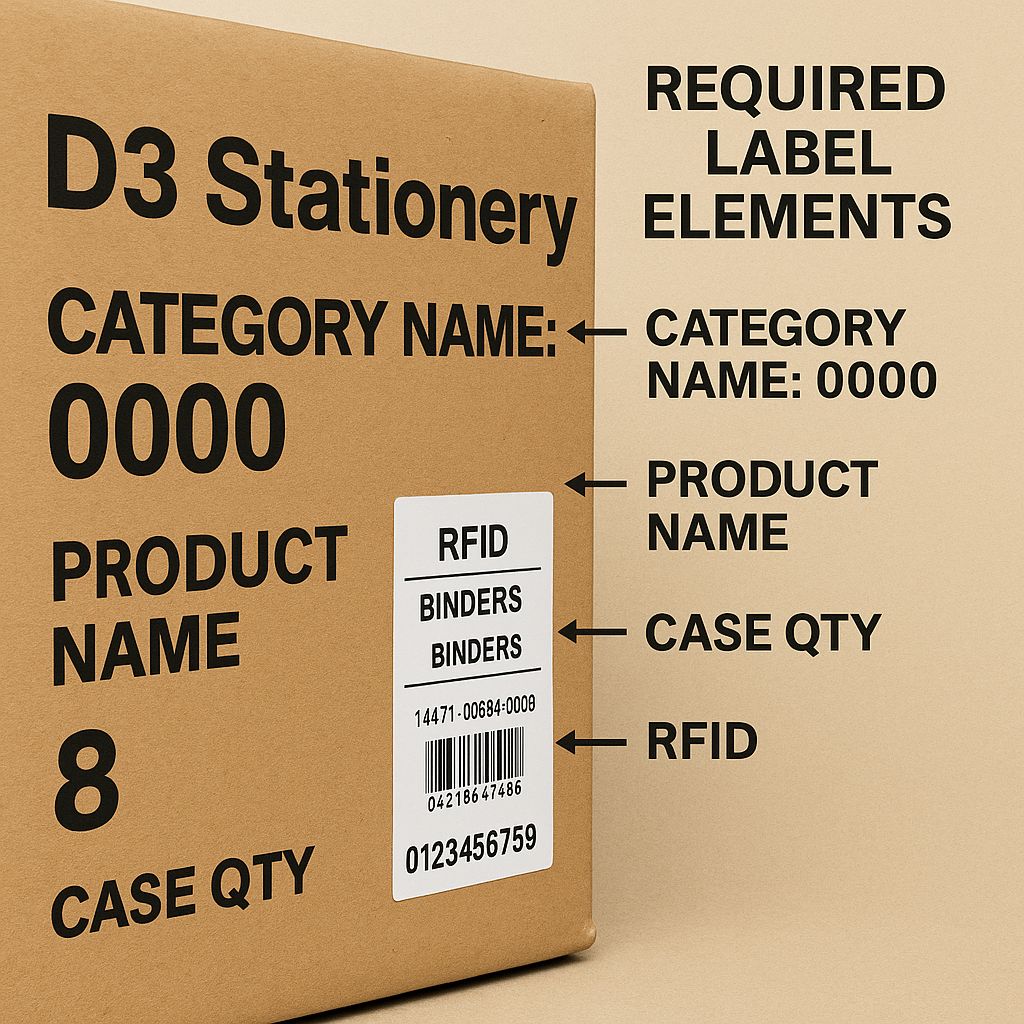

Each shipper must include the following information:

Why this matters: Walmart uses RFID and barcodes for automated inventory management. Missing or misprinted labels can result in rejected shipments.

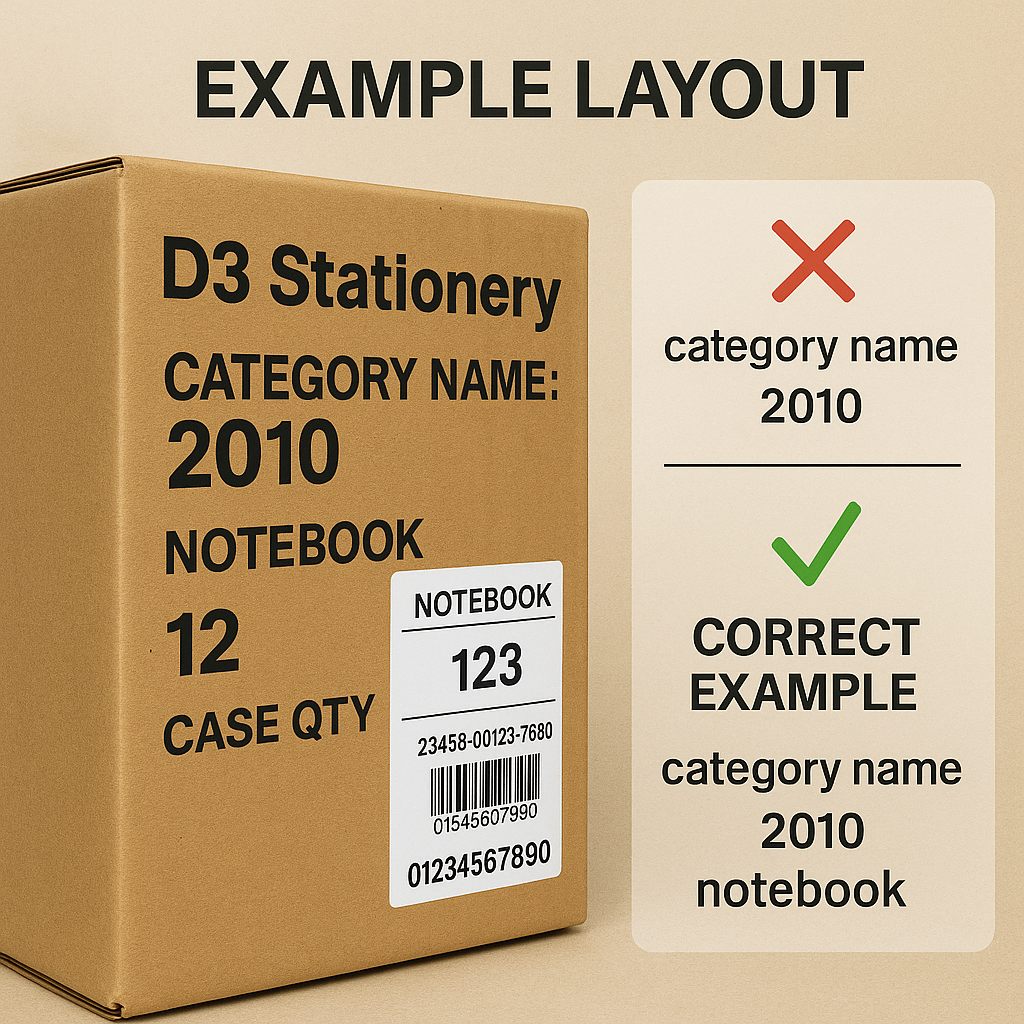

The standard example shown includes:

This template isn’t optional—it must be followed consistently across all cartons.

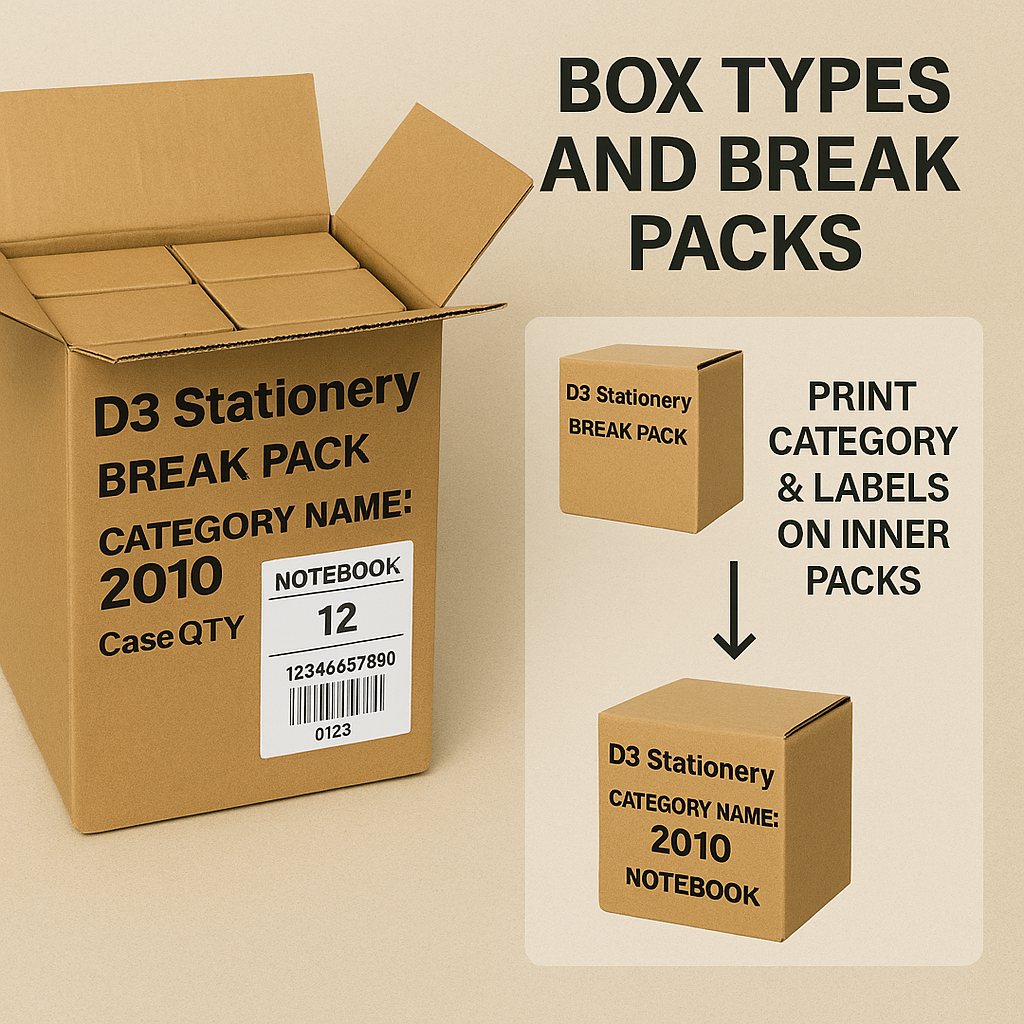

The standards also show break pack options—larger master cases containing smaller shipper boxes inside. Each sub-pack must follow the same labeling rules.

Why this matters: During busy BTS seasons, Walmart often breaks pallets into smaller units for fast store distribution. If inner packs are unlabeled or inconsistent, stores waste time reprocessing.

Here’s a snapshot of some 2025 D3 category numbers and names (based on Walmart’s provided chart):

Each number ties directly into Walmart’s category management system, ensuring that cases are routed correctly from DC (distribution center) to store shelves.

To comply successfully with the 2025 standards, suppliers should adopt these practices:

With RFID now standard across Walmart’s supply chain, technology plays a larger role than ever:

Tip: Invest in RFID label verification tools and barcode graders—these small investments can save thousands in penalties.

Walmart’s packaging rules are not just about compliance—they tie into the retailer’s larger goals:

For suppliers, aligning with these goals not only avoids problems but also strengthens long-term partnerships.

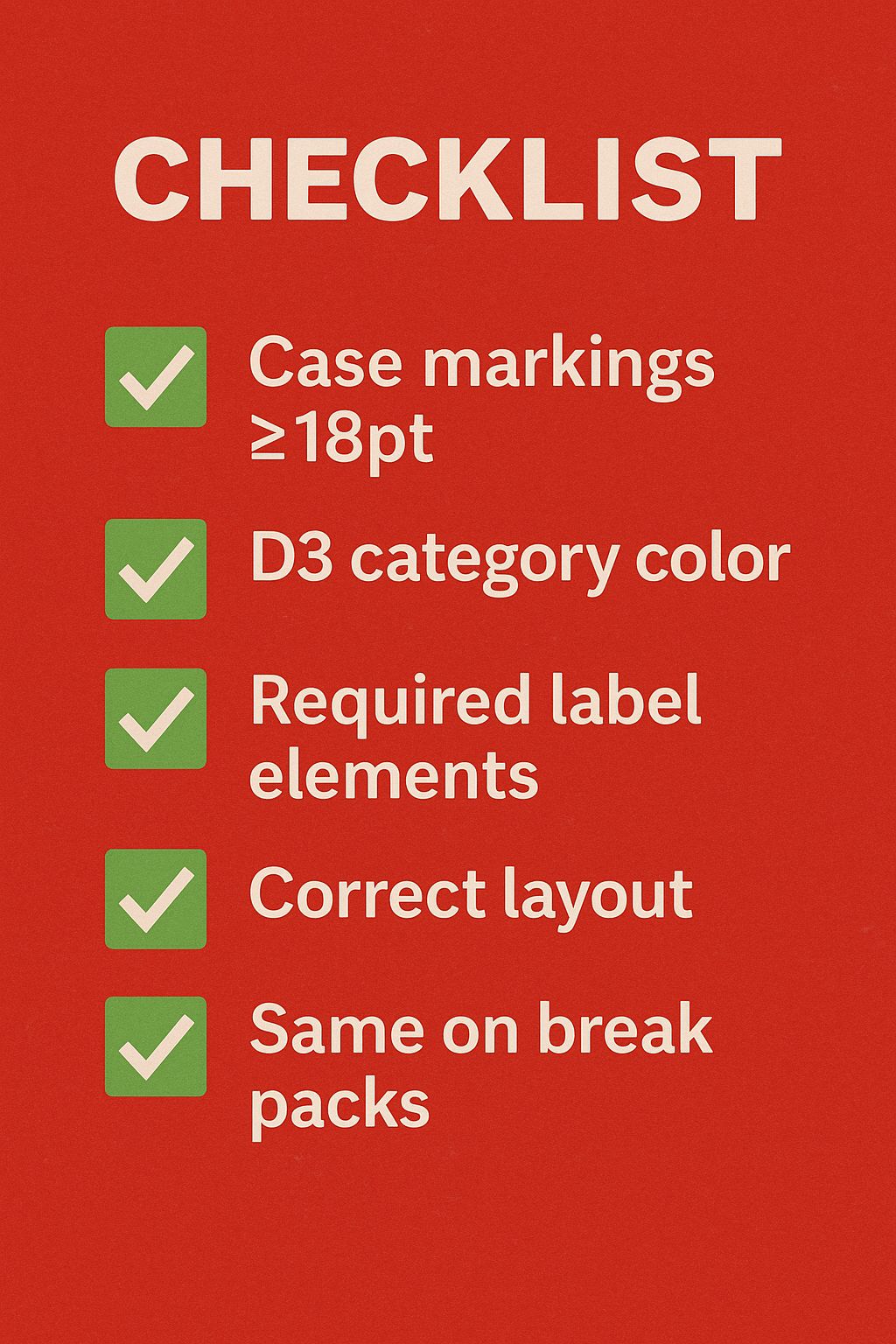

Here’s a quick compliance checklist before you ship:

If you can check every box, you’re ready to ship.

Walmart's 2025 D3 Category Box Standards may look detailed and rigid, but they exist for good reason. By enforcing consistency across millions of cartons, Walmart ensures efficiency, accuracy, and sustainability in one of the busiest retail supply chains on earth.

For suppliers, compliance isn’t just about avoiding chargebacks—it’s about proving you can meet Walmart’s operational expectations and deliver at scale. With back-to-school season driving huge demand, the stakes are high, but with preparation, your shipments can flow smoothly and profitably.

Bottom line: Get the markings right, follow the category rules, and use technology to stay ahead. Compliance today means stronger retail relationships tomorrow.

Links