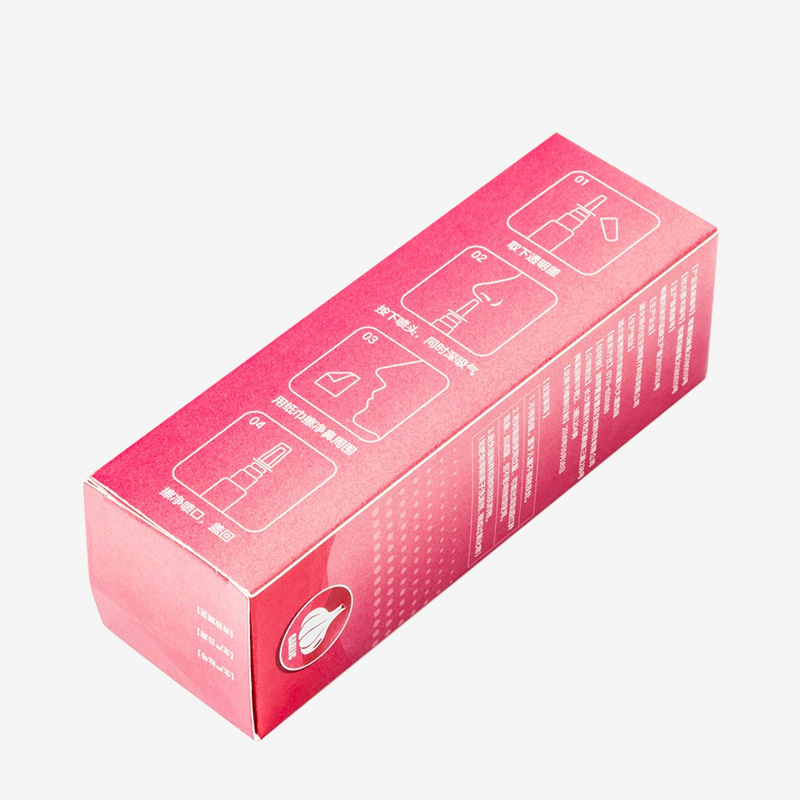

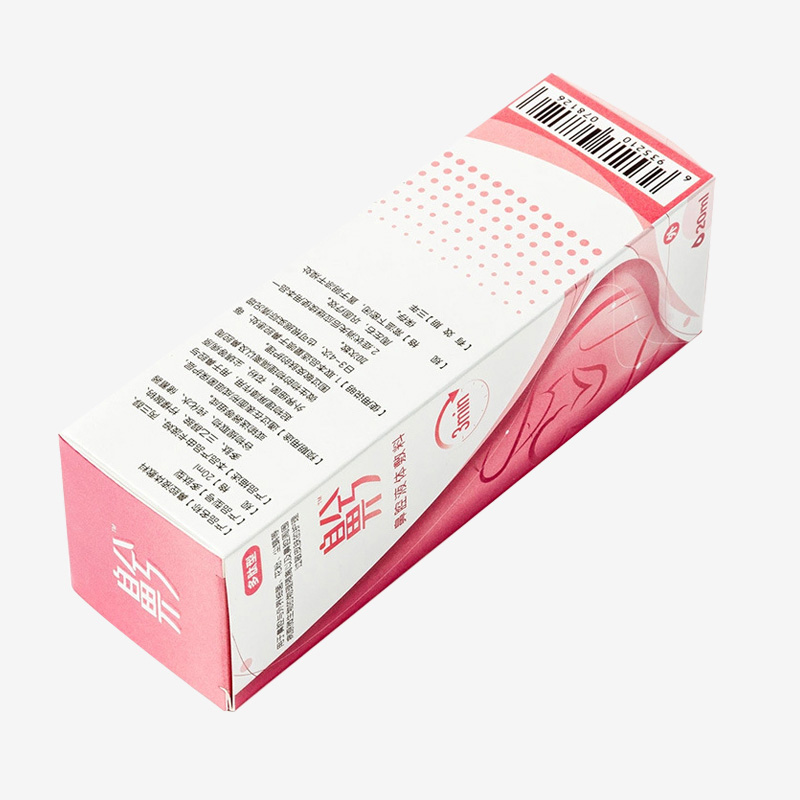

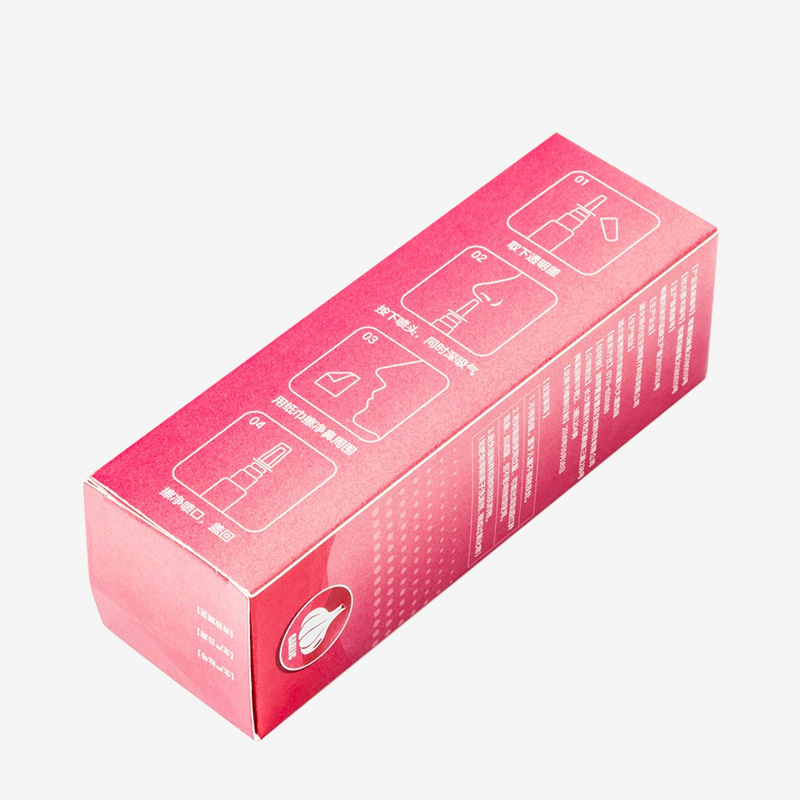

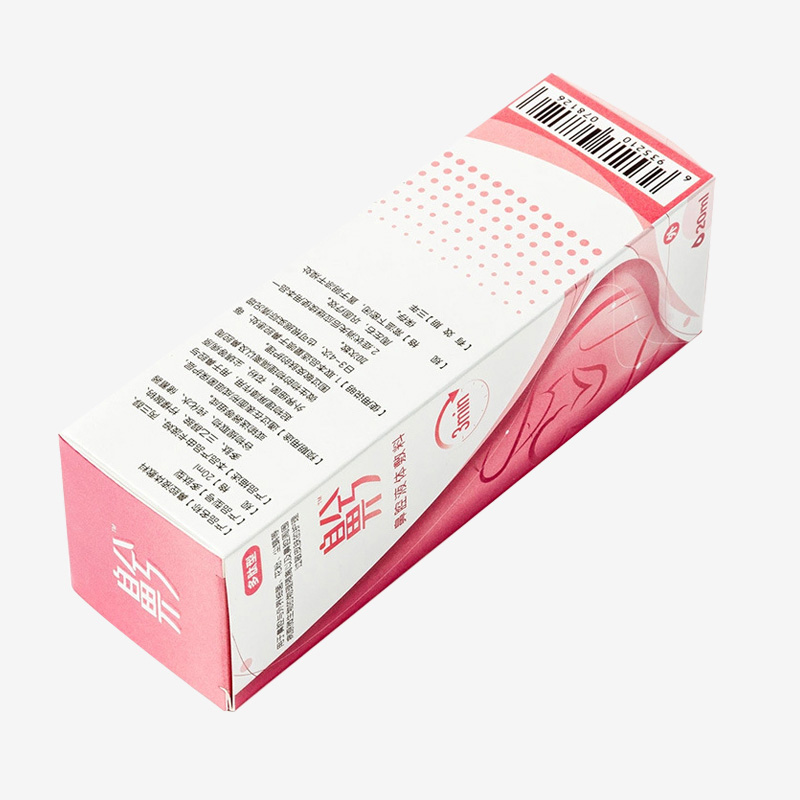

Custom-made medical packaging box medical nose-sucking color printing

paper box white cardboard oil-covered and film-covered medicine socket type packaging box

1. Packing box size and specification:

* Box size: Please provide the length, width and height of the box you need, and the size of the medicine storage area.

* Box shape: Is it a regular square/rectangle or a special shape?

* Box thickness: the gram weight of white cardboard determines the box thickness.

It is recommended that you choose the appropriate gram weight according to the weight of medicine and transportation needs.

2. Color printing design:

* Box design: Please provide the design elements you want, such as patterns,

colors, fonts, logo, and the brand information and product features you want to convey.

* Printing process: Apart from conventional color printing, do you need special printing processes,

such as bronzing, UV, embossing, etc?

3. White cardboard material and film covering:

* Weight of white cardboard: It is recommended to use more than 250g of white cardboard to ensure

the strength and durability of the box.

* Film covering type: Commonly used film covering types include bright film, matte film and pearl film.

It is suggested that the suitable film covering type should be selected according to the product positioning and market demand.

4. Drug socket design:

* Socket position: the socket position needs to match the size of the medicine to ensure convenient access and safety.

* Socket design: factors such as the shape, size and installation mode of the socket need to be considered,

which is safe, beautiful and convenient to use.

With 14+ years of industry experience, we have a better understanding of customer needs.

Heidelberg professional printing machine Solve printing color difference, printing speed and shorten delivery time.

Certificate of honor

Six commitments of field manufacturers

|

|

|

| Customer service one-on-one service, quickly solve all kinds of product problems for you. | We offer hundreds of high-quality raw materials for you to choose from. All products can be confirmed by proofing first. |

|

|

|

| 4 professional automatic paste box production line machines | From design, production, quality control, logistics, Everything is available after sale, and we will do all the work. |

|

|

|

| Formal invoice size and amount can open VAT invoice enterprise, normalization | Sales service team The 20-person customer service team is online all day. At any time to solve problems encountered. |

Selected materials of Yuantou factory

Please consult for more options.

|

|

|

|

|

| corrugated paper | kraft paper | Specialty paper | The gold card paper |

|

|

|

|

|

| Silver cardboard | Black cardboard | White cardboard | art paper |

Surface Treatment

It can be made from design, plate making and printing to later die cutting,

concave-convex UV and film covering.

|

|

|

|

| Silver ironing process | Bronzing process | Concave and convex process |

|

|

|

|

| UV process | Bright film process | Dumb film process |

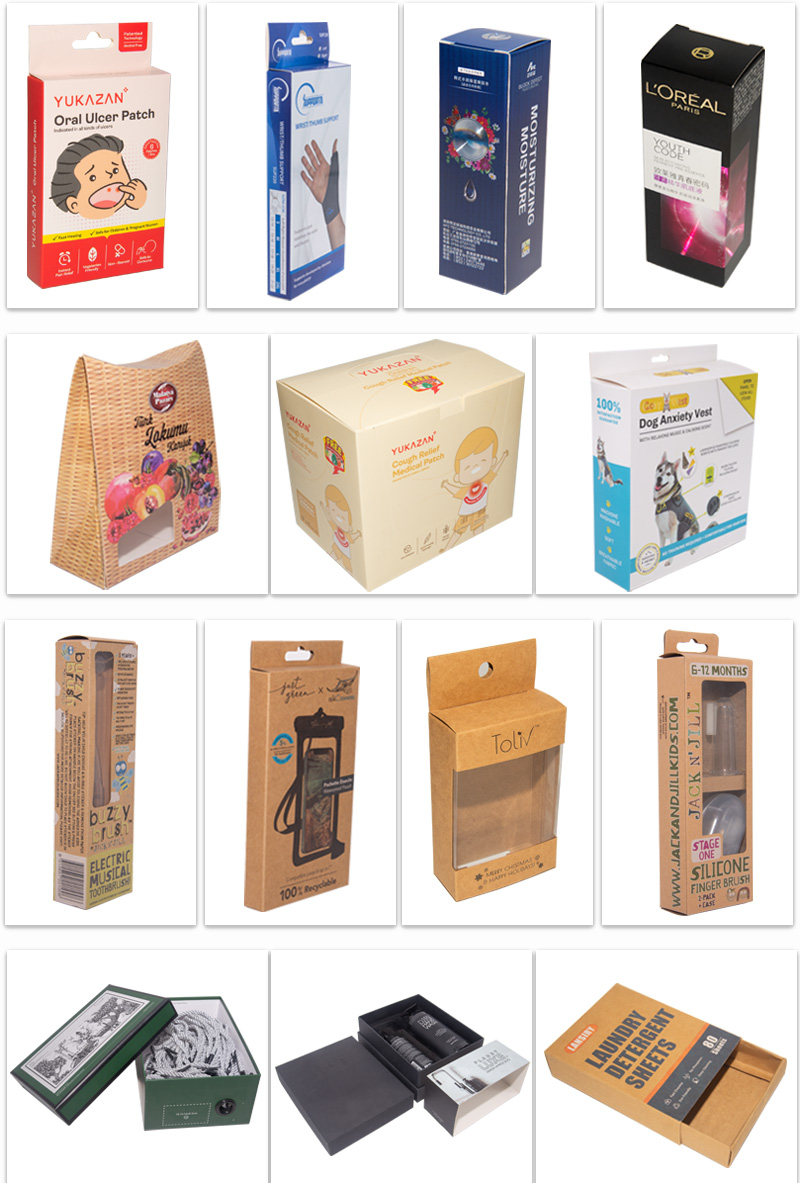

Partial case box type

Can be made of different box types and materials, please consult customer service.

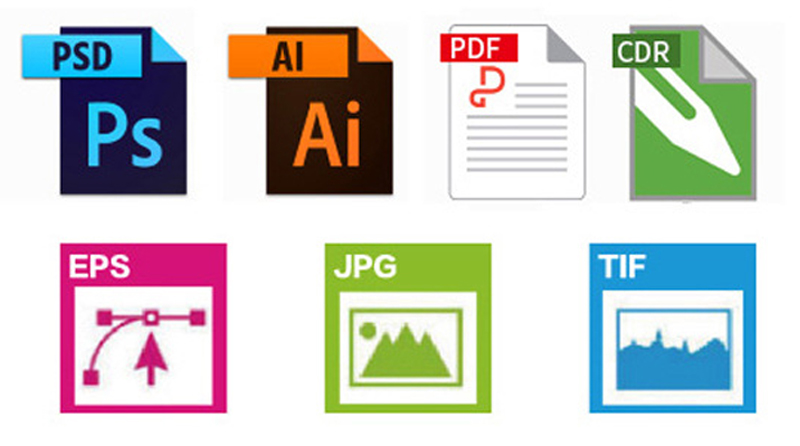

Customer submission requirements

For the documents provided by customers, it is recommended to use (CDR, AI, PS, PDF, EPS)

and other vector formats can also provide high resolution if they do not have the above file formats.

(more than 300dpi) JPG, TIF format files As for some files made by office software, Files in formats

such as word and excel are not up to standard for color printing. Of course, there is no problem

for monochrome printing and inkjet printing.

For the documents provided by customers, it is recommended to use (CDR, AI, PS, PDF, EPS)

and other vector formats can also provide high resolution if they do not have the above file formats.

(more than 300dpi) JPG, TIF format files As for some files made by office software, Files in formats

such as word and excel are not up to standard for color printing. Of course,

there is no problem for monochrome printing and inkjet printing.

Partial box display

|

|

|

|

|

| Up-down intubated box, window opening Paste PVC/PET | Insert the locking buckle into the intubation box up and down, and hook the box. | Insert the locking buckle into the intubation box up and down, and hook the box. | Stick PVC/PET on the window of the intubation box from top to bottom. |

|

|

|

|

|

| Tie packaging design, display box Packaging design | Electronic product packaging design, tray carton packaging, gift box packaging design | Display box packaging design, jewelry packaging design, packaging structure design | Design of hexagonal packaging box and special-shaped packaging box |

|

|

|

|

|

| Tiandi cover enclosure, corrugated cardboard box, transport carton, folding carton, binding | Cartons, corrugated boxes, single-layer cardboard boxes, three-layer corrugated boxes | Design of heaven and earth cover, trapezoidal box structure and special-shaped box structure | Tiandi cover carton, corrugated carton transport carton, folding carton, binding |

|

|

|

|

|

| Packaging carton design | Shoe box packaging design, packaging box design, packaging design description | Gift box packaging design, international standard box type, packaging box design | Express packaging box design, self-locking tray box, tray carton, flip box |

|

|

|

|

|

| Combined packaging design, drawer box packaging, folding molding, underwear and socks pumping | 5-sided sealed drawer box, box, drawer box packaging, folding molding | Window packaging, drawer folding carton electronic product packaging food packaging | Drawer box packaging, folding underwear and socks drawer box |

|

|

|

|

|

| Glued sleeve box | Glued sleeve box, locking structure, enclosure, external seal | Six display boxes, beer cartons, handle cartons, 6-bottle carton structure | Sunshade display box, display box packaging design, small jewelry packaging design |

Factory scene

|

|

|

| make plate | Heidelberg printing machine printing |

|

|

|

| Color correction | Printed matter inspection |

|

|

|

| tectorial membrane | Hot stamping and silver stamping |

|

|

|

| die cut | Printed matter inspection |

|

|

|

| Automatic paste box | examination of material |

Customer notice

About color difference

Due to the different resolution of the monitor and the different shooting light and environment, it is normal that the color difference

of the actual printing will be about 15%, and different batches and versions of printing will also produce color difference,

so it is impossible to print the same color twice, and whether the product is covered with film will also affect the actual color

of the printed matter, and it is normal to have a little color difference.

Links